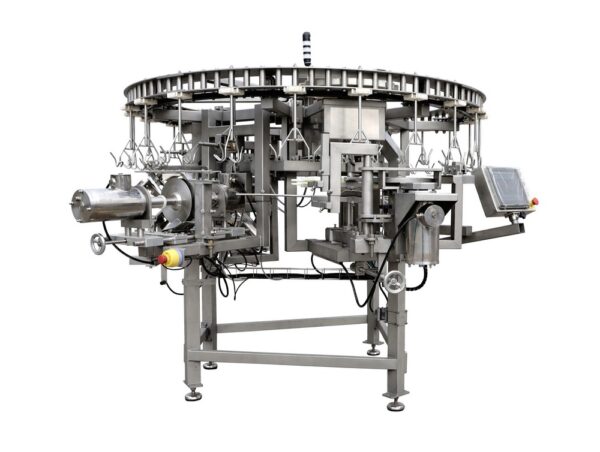

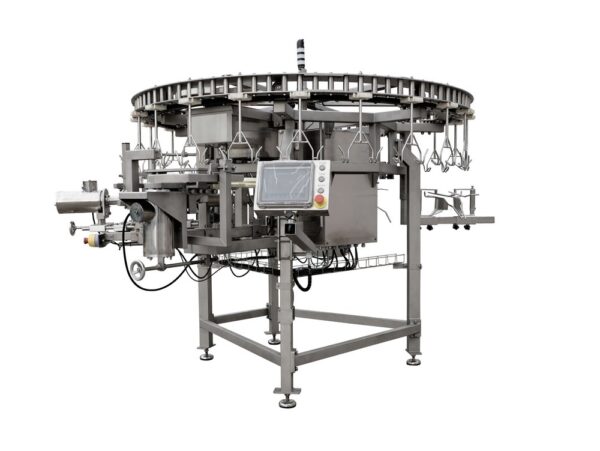

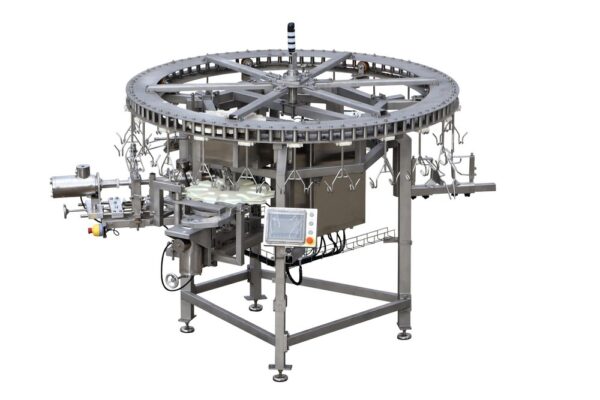

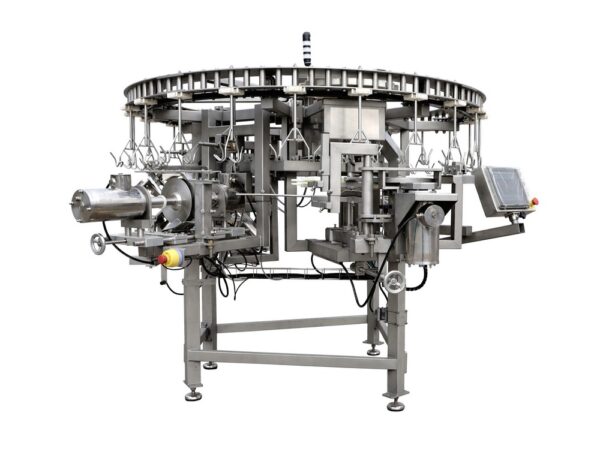

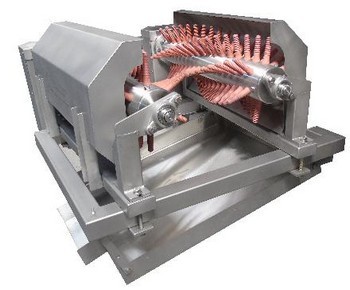

Automatic Carousel Divider

Product description

Automatic poultry cutting machine designed for cutting carcasses into anatomical parts.

OPERATION

The automatic carousel cutter consists of a main frame to which the cutting modules are mounted. The operation of individual modules is controlled via an electrical cabinet integrated with the cutter. The standard version of the cutter includes the cutting modules listed below, but the investor can choose only a few of them.

1. Wing straightening

The wing straightening module is designed for the initial positioning and straightening of poultry wings to ensure the correct functioning of the next wing cutting module. The chicken is transported suspended on stirrups facing the direction of movement. The wings are straightened by two steel guides as the chicken passes through the device. The module is easy to operate and set up as it does not contain any moving parts.

2. Cutting off the entire wing

The entire wing cutting module consists of two cutting units symmetrically positioned relative to the centre line of the stirrups. Two rotating knife discs are mounted on shafts and driven by electric motors. The chicken carcasses are transported into the machine with their backs facing the machine and are passed through it in a horizontal position. The wings are positioned correctly for cutting by steel guides. The cut wings fall into a container or onto a conveyor belt.

3. Tube cutting

The next tube cutting module easily cuts the front part of the carcass from the rear part with the legs in this configuration. This cut is made by a rotating knife as the carcass is passed sideways and positioned correctly by steel guides. The front part of the carcass falls into a container or onto a conveyor belt.

4. Adjustable cross-cutting module

The adjustable cross-cutting module is designed to divide the remaining part of the carcass into two or three parts. The spine is separated from the legs and falls freely into a container or onto a conveyor belt. The two knife blades can be adjusted so that the rear part of the carcass is divided into only two parts along the spine.

5. Thigh-shank cutting

The thigh-shank cutting module performs an anatomical cut through the joint and separates these two parts from each other. The two legs are precisely positioned by a separating wheel before the thigh is cut off. The cut thigh falls into a container or onto a conveyor belt while the shank is transported to the next module.

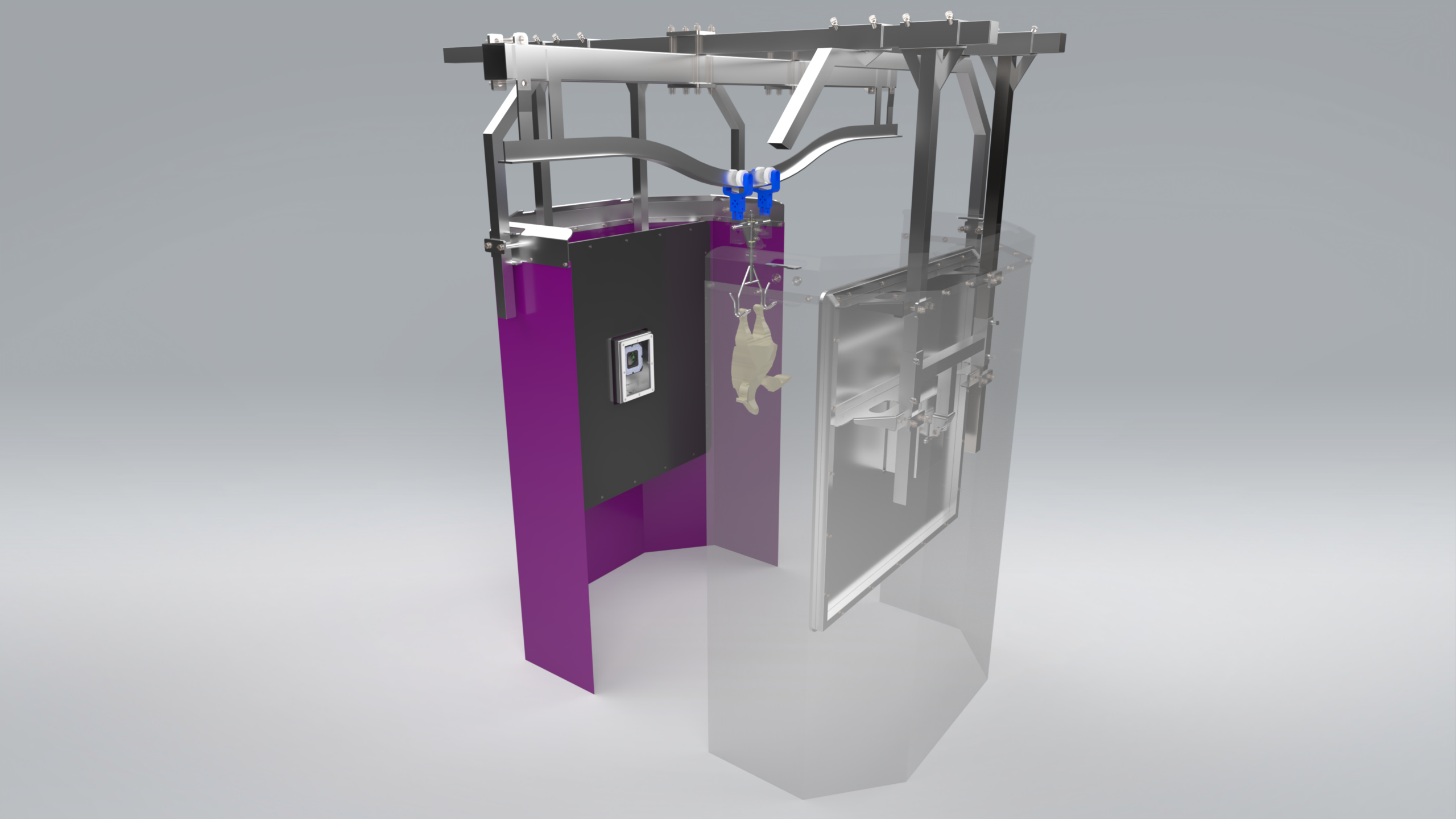

6. Unhooker

The unhooker is the last module in which the lower leg is released from the stirrups and falls freely into a container or onto a conveyor belt.

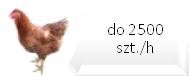

ADVANTAGES

-Compact design, small size

-Maintenance-free

-The size of the device is adjusted so that the divider, in a complete, assembled state, can be transported by road to the investor's plant without the need to dismantle individual dividing modules.