Belt Weighing Sorting

Product description

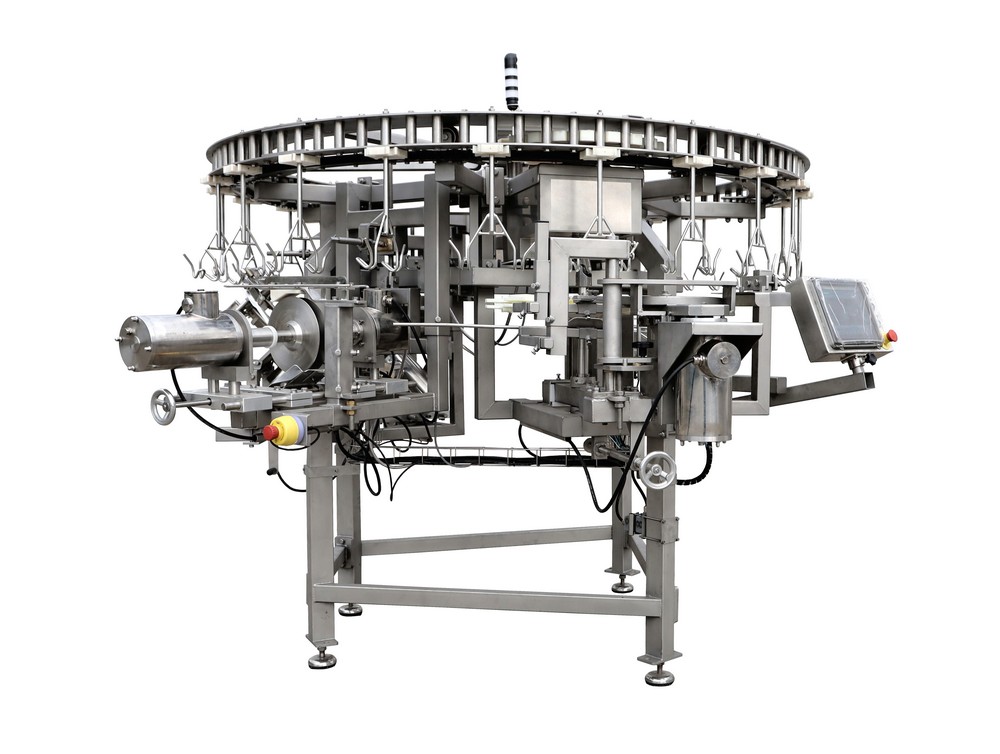

Belt weight sorting is used to sort slaughtered poultry carcasses or separated poultry carcass parts.

OPERATION

The items to be sorted can be fed automatically (e.g. by means of a belt conveyor) or manually. In both cases, the items to be sorted must be placed on the loading conveyor. Correctly loaded pieces are fed onto the weighing conveyor and then onto the sorting conveyor, where scrapers sort the pieces according to the set parameters. The sorted items fall into containers via a chute. The computer system decides which scraper to activate, sending a signal to the appropriate scraper so that each container contains the correct portion of carcasses or sorted items, in accordance with the set parameters. When the container is full (according to the parameters entered into the system), an indicator light comes on (separate for each scraper). After replacing the container with an empty one, press the button next to the chute to signal to the computer system that the container is empty and a new batch of sorted items can be added to it.

ADVANTAGES

-High accuracy

-Wide range of weight settings

-Improved packaging